How to choose and install a suitable drag pointer pressure gauge

Aug 11, 2020|

Aug 11, 2020| View:1159

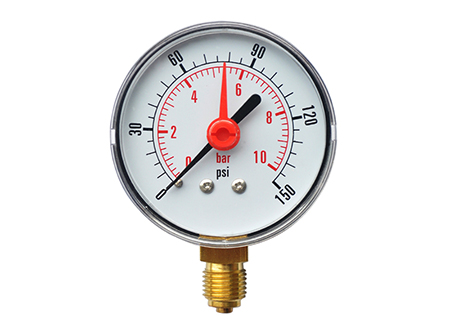

View:1159Many aspects need to be considered when selecting and installing a resistance pointer pressure gauge suitable for the system.

Let's talk about options first. There are three main selection points: type, range and accuracy level.

1. Type: When typing, what needs to be considered is the display mode, pointer or digital display requirements; the physical and chemical properties of the measured medium, the toxicity and corrosiveness of the gaseous liquid; whether the site environmental conditions are abnormally hot. For example, choosing pressure gauges (such as oxygen and hydrogen) has its own considerations.

2. Range: the range of working pressure change. How many atmospheres to several atmospheres? If the state is different, for example, steady pressure, pulsating pressure and high pressure each have different requirements.

3. Accuracy grade: This reflects the maximum measurement error allowed by the range and process, and the maximum allowable error can be derived from it.

After the selection is over, let us discuss the installation.

1. Select the measuring point

Just like choosing the location of the plant, it is also important to check what to measure and where to measure before installing the pressure gauge. The measuring point is best in the straight pipe section where the measured medium flows in a straight line. The pressure measuring point should be perpendicular to the flow direction, and the end surface of the pressure measuring tube should be flush with the inner wall of the device connection, and there should be no protrusions such as burrs, otherwise it will affect the fluid flow state and affect the flow rate, thereby affecting the local pressure. When measuring liquid pressure, the pressure point should be at the bottom of the pipe to prevent air from accumulating in the air duct. When measuring air pressure, the pressure point should be above the pipe to avoid liquid accumulation in the draft tube.

2. Install the pulse tube

The thickness of the pressure pipe should be appropriate so as not to cause unnecessary trouble; when the measured medium is easy to condense or freeze, an insulation heat tracing pipe must be added to ensure the accuracy of the measurement; a piece should be added between the pressure port and the pressure gauge valve Cut-off point: When installed horizontally, the pressure guiding tube should have a certain inclination.

3. Install the pressure gauge

Install in a location that is easy to maintain and observe, such as panel installation; try to avoid vibration and high temperature, so as not to damage the instrument or affect the measurement result; the installation height should be the same or close to the pressure point, otherwise measurement errors will occur; when measuring vapor pressure, install the panel Tube (circled tube) to prevent high temperature steam from directly contacting the component under test. The corrosive medium should be added with isolation tank; the connection between the pressure gauge and the pressure pipe should be installed with a sealing liner to prevent leakage; the exhaust valve, stop valve, and balance valve should be used correctly.

The ordinary pressure gauge is also an essential part of the automation system. I hope you can select and install a suitable pressure gauge for your system.

The thickness of the pressure pipe should be appropriate so as not to cause unnecessary trouble; when the measured medium is easy to condense or freeze, a heat-preserving heat tracing pipe must be added to ensure the accuracy of the measurement; a piece should be added between the pressure port and the pressure gauge valve Cut-off point; the pressure guiding tube should have a certain inclination when installed horizontally.

View More(Total0)Comment lists