. Large, clear and easy-to-read 4" dial

. 4-20mA standard two-wire output

. Accuracy: ±2%FS. Below 125Pa 4%

.Magnetic spiral radio frequency non-contact technology

. Save time, money, space

0

0KB2000DU is a two-in-one product of mechanical meter and transmitter, providing clear and easy-to-read pointer indication and standard two-wire 4-20mA current output function. The measuring range ranges from 0-60Pa to 0-10KPa, and can be used for positive pressure, negative pressure, and differential pressure measurement. It is suitable for non-flammable gases and has a full-scale accuracy of ±2%.

Main feature:

. Mechanical Micro Differential Pressure Gauge Micro Differential Pressure Transmitter 2-in-1

. Large, clear and easy-to-read 4" dial

. 4-20mA standard two-wire output

. Accuracy: ±2%FS. Below 125Pa 4%

.Magnetic spiral radio frequency non-contact technology

. Save time, money, space

Application:

. Cleanroom

. Fan, blower pressure

. Filter resistance

. Wind speed, furnace pressure

The KB2000DU pointer meter/transmitter uses a simple, frictionless magnet spiral movement and uses a rubber diaphragm as a sensitive element to measure. It can use the pointer to quickly indicate the pressure of the gas being measured, whether it is positive pressure, negative pressure or differential pressure. pressure. This design is shock, shaking and over-pressure resistant. Moreover, there is no need to fill the watch with liquid, so there are no problems with vaporization, freezing, or odor. At the same time, radio frequency non-contact measurement technology is added to convert the displacement of the diaphragm into a standard 4-20mA current output.

The KB2000DU pointer meter/transmitter uses a simple, frictionless magnet spiral movement and uses a rubber diaphragm as a sensitive element to measure. It can use the pointer to quickly indicate the pressure of the gas being measured, whether it is positive pressure, negative pressure or differential pressure. pressure. This design is shock, shaking and over-pressure resistant. Moreover, there is no need to fill the watch with liquid, so there are no problems with vaporization, freezing, or odor. At the same time, radio frequency non-contact measurement technology is added to convert the displacement of the diaphragm into a standard 4-20mA current output.

Instrument installation:

Installation environment: Ensure that the measurement range is met, the temperature range is met, and strong vibration is avoided.

Installation direction: Factory calibration and use must be performed with the diaphragm vertical to the ground.

Installation method: Embedded installation Surface installation

Electrical connections:

There is a plastic aviation socket behind the case of the 2000DU pointer transmitter, which is connected to the corresponding plug. The plug has two red and black power cords, red is positive and black is negative, which are connected to the positive and negative terminals of the DC power supply respectively.

Zero point adjustment:

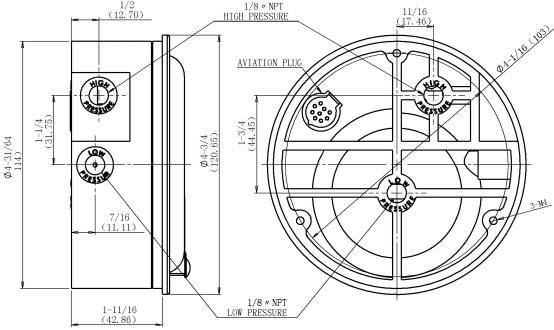

After the installation of the 2000DU pointer transmitter is completed, when there is no connection pressure, the customer should carefully check whether the pointer is at the zero position and check whether the current output is 4mA. If the pointer indication is not at zero, gently rotate the zero adjustment screw on the panel. If the current is not 4mA, unplug the zero-adjustment sealing plug near the aviation plug on the back of the instrument (see the dimensional drawing), insert a screwdriver to adjust the zero, and be sure to plug the sealing plug after the adjustment is completed.

RM 1506-1508,Jincheng Building,NO.368 HanJiang Road, Xinbei District, Changzhou,Jiangsu,China

+86-519-88108199

info@czkb.net

+86 13815025973

1464346284

CopyRight © 2024 Changzhou KB Instruments & Meter co.,ltd. All rights reserved Sitemap All tags